It is important to understand the difference between pull flow and push flow, a very important difference in the Kanban world.

The concept of push flow

Each person on a production line will push his work to the next person; the latter has the constraint to take work when there are available work for him. That is the push flow.

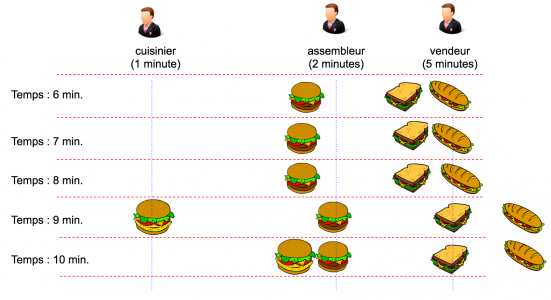

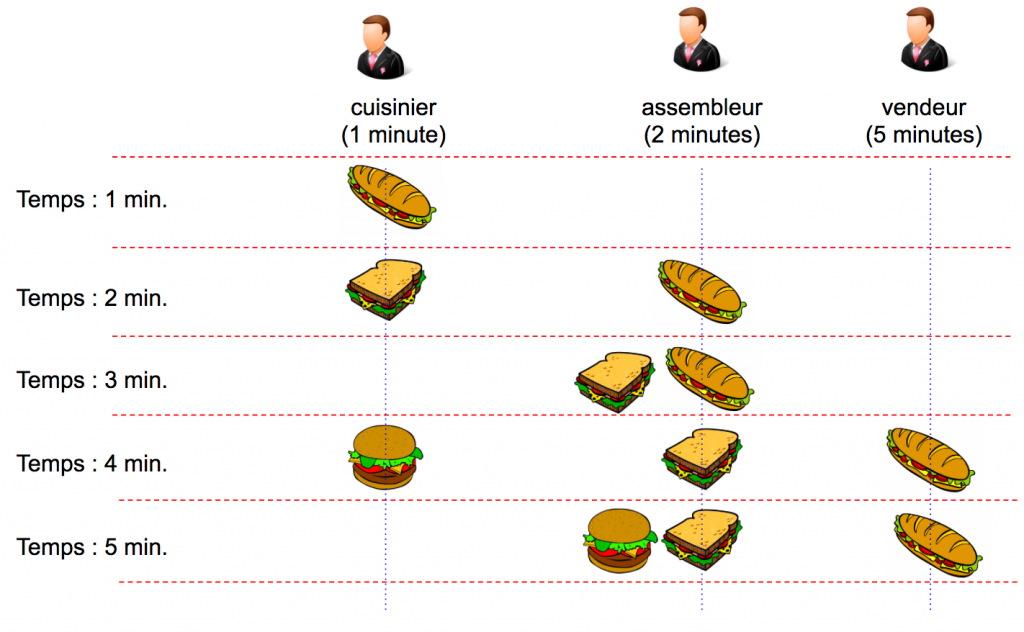

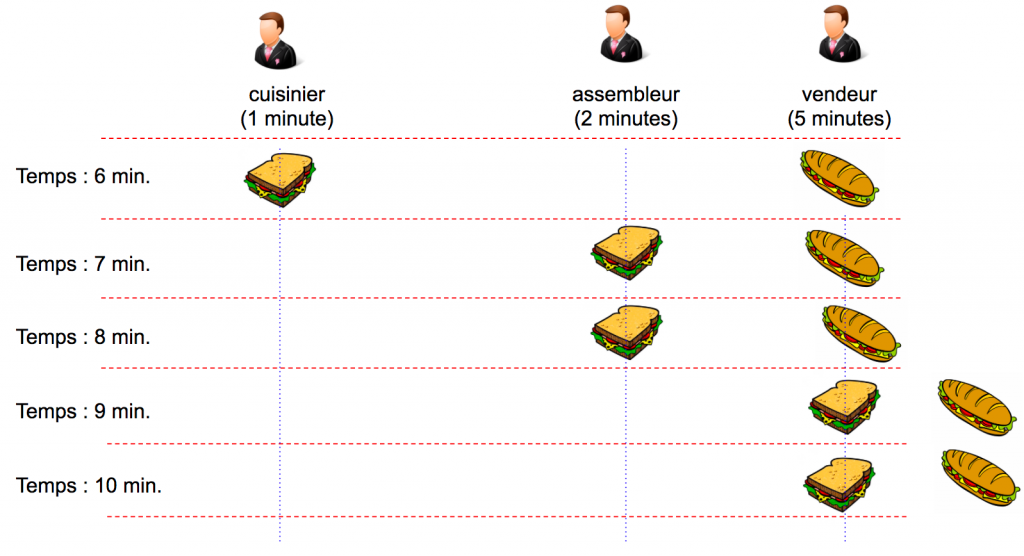

Let us take a simple example, a fast food restaurant that wants to sell sandwiches to its customers. We will have a production line as in a factory to go from cooking items to selling the sandwich.

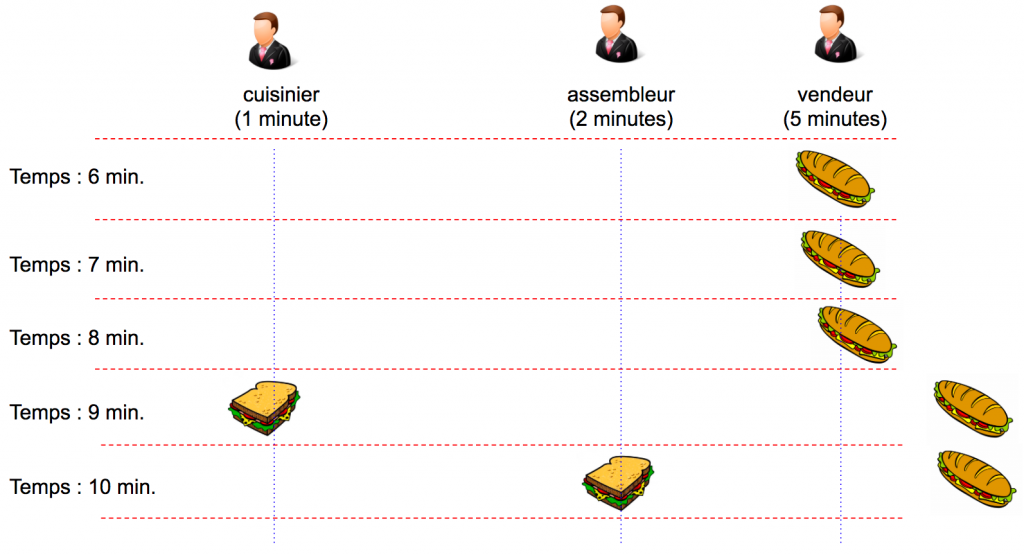

We have in our line 3 steps but each step doesn’t always take the same time. In this case of push flow, we have a lot of sandwiches waiting in step 2.

Considering the delay of 5 minutes for the sale of the sandwich, you can imagine that we will have the same storage problem in the step 3 because the time of sale is even greater than the delay of the sandwich assembly.

If we decide to see what would be the result of this product line, you will see that the sandwich would take too much time to reach the customer and the latter would be cold in his hands. And this phenomenon will be more and more true by advancing in time.

You will understand that we are in an inefficient situation. We will not be able to store indefinitely. And if we want to please our customers, we will be forced to throw or cook again sandwiches.

There will be a lot of losses and it will cost us money.

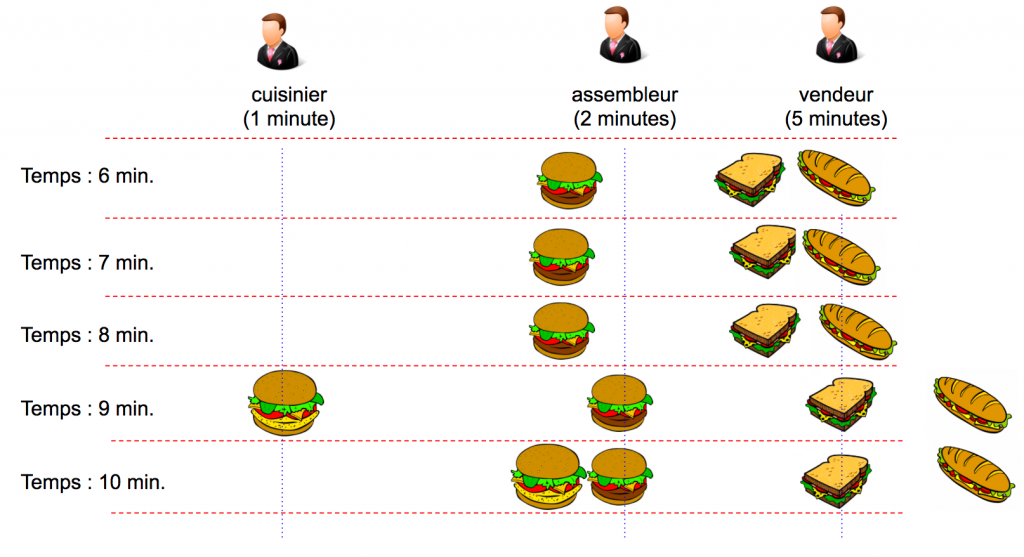

Pull flow

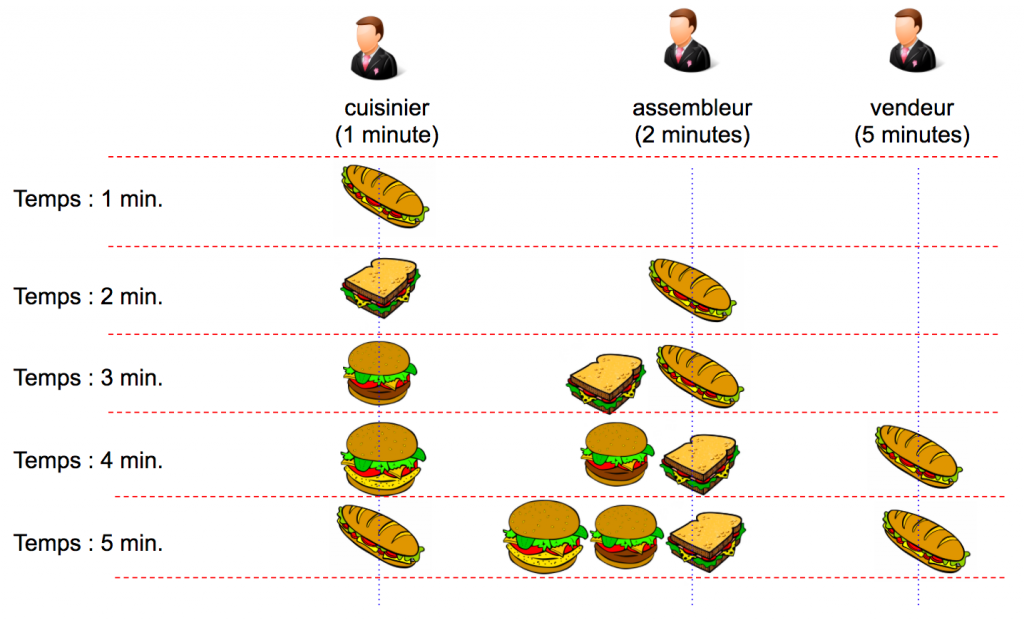

To fill these concerns that we have encountered in our sandwich production line, we decide to change our methods and do things only on demand.

Here is a concrete example to understand what is the pull flow:

Indeed the cook will cook only when there is demand. On the second phase, we will have this:

We can see several phenomena occur with this new mode of production:

- My cook worked only 2 minutes out of 10. Indeed we could allow to assign him other tasks useful for the company. We have the similar phenomenon with our other actors in the production line

- Our client will always be forced to wait 9 minutes for his sandwich which is not very good on the other hand.

- Our customer will always have a hot sandwich which he will particularly appreciate.

- There is no longer stock and waste so my company now loses much less money (food, electricity …). This is a very positive point.

You will understand, this model is not ideal because if it offers very advantageous points but also the disadvantage to add waiting to our customer; we see the beginning of an optimal solution.

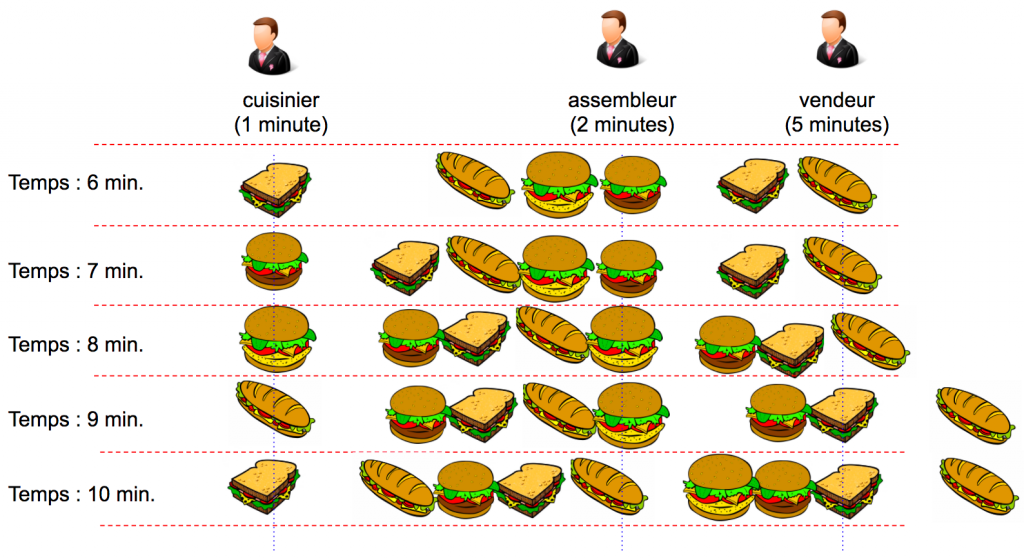

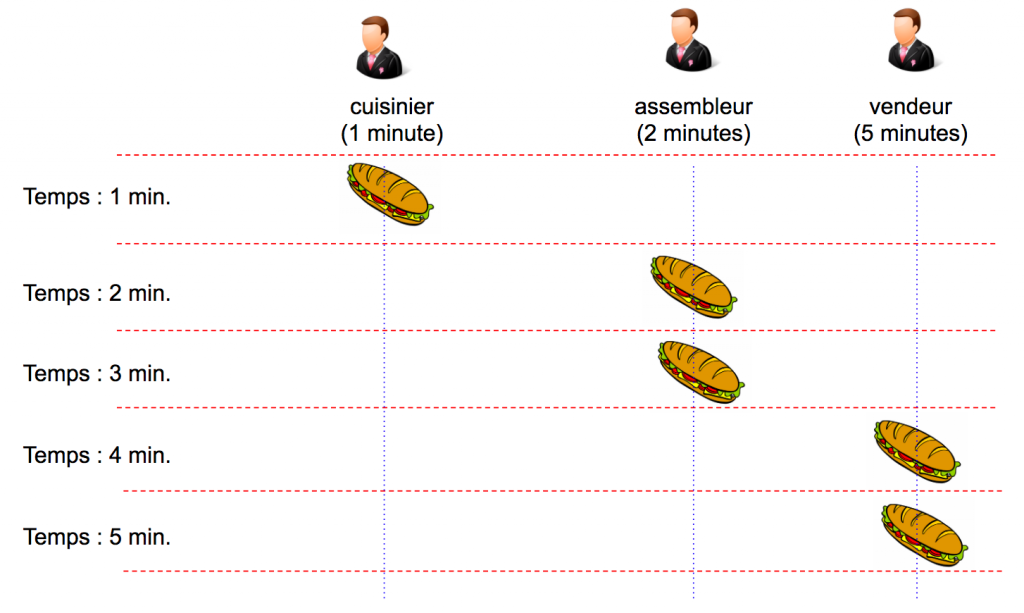

The pull flow with intermediate stock

We decide to use a model that will fill the last problem that we encountered: the longer waiting period for the customer. So, we will allow ourselves to have an intermediate stock between each step like this:

This time, our cook will begin cooking the sandwich elements when it miss 1 stock in advance in the next step of the production line.

We have just made up the disadvantage to make the pull flow thanks to the notion of intermediate stock of 1. The evolved kanban board uses this concept

Now, I would say that there is a small flaw that appears in our product line; the sandwich may be less hot with this method. In the world of agility, we want a completely satisfied customer.

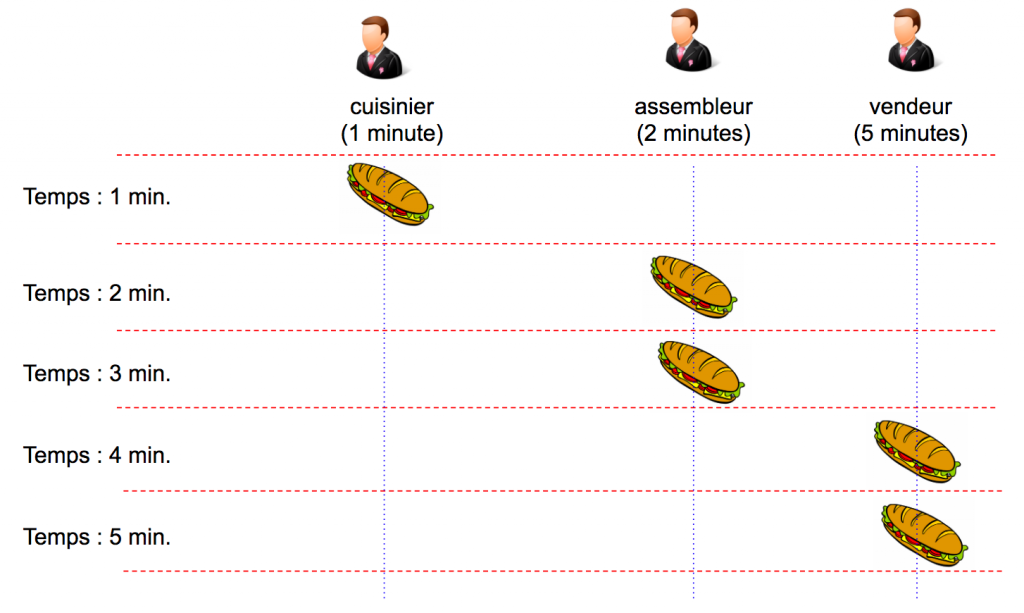

Pull flows with intermediate stock at controlled time

So, I will propose you another improvement of the tense flow; however, it will not always be possible to do it in IT. Indeed, we know that defining deadlines in an IT development is often utopian.

But this article does not necessarily concern the development of an application but it can concern all sectors of a company.

So, we will start the cooking only at the right moment to optimize the production line as much as possible. Here is an example :

The sandwich will arrive exactly at the same time in the hands of the customer but it will be started 4 minutes later. The sandwich will be surely hotter and our customer will be really more satisfied.

Maximum optimization

However, if the examples are simple, in general, we have to calculate the time between two purchases at different times of the day; that will optimize the production line because the output changes according to the hours.

However, some will stop at the third step “the pull flow with intermediate stock” to fill the risk of uncertainty to see many customers arriving the same minute. Some will even increase the intermediate stock or increase the number of sellers to two to fill this production line.

Conclusion pull flow

You will have understood that Lean and Kanban have brought this notion of pull flow which is really beneficial compared to the push flow. Now, these notions of push flow and pull flow have no more secret for you.

1 Trackback / Pingback